What are hard hats made of?

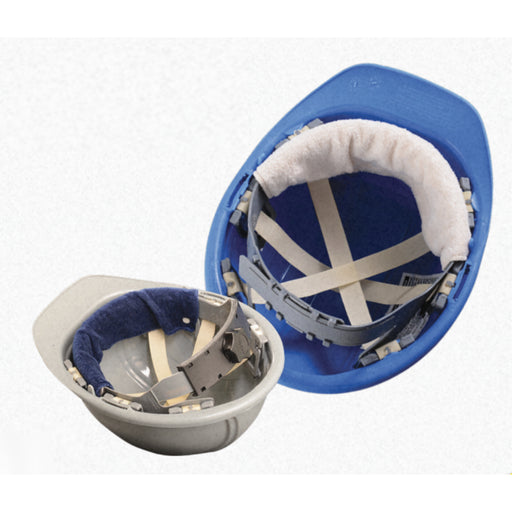

Hard hats are made from high-quality materials such as high-density ABS (Acrylonitrile Butadiene Styrene) or Polyethylene, providing strength and durability. They are designed with adjustable suspension systems for a secure fit and include replaceable sweatbands for added comfort.

What are the different types of hard hats?

Hard hats are classified based on their material, type, class, and safety standards. They are typically made from durable materials like ABS (Acrylonitrile Butadiene Styrene) or HDPE (High-Density Polyethylene). Additionally, hard hats must meet specific safety protection standards, such as ANSI Class G (General), Class E (Electrical), and Class C (Conductive), to ensure proper protection in different work environments.

What do the different color hard hats mean?

Different colored hard hats signify specific roles and responsibilities on a worksite. White for site managers, foremen, engineers, or supervisors, Green for safety inspectors or new/probationary workers, Yellow for general workers or earth-moving operators. Brown for workers involved in high-heat applications, such as welding. Blue for carpenters, electricians, and other technical operations.

What is the difference between Type 1 and Type 2 hard hats?

Type 1 and Type 2 hard hats both provide head protection but differ in the type of impact they guard against. Type 1 hard hats are designed to protect against impacts and blows from above, providing top-only protection. Type 2 hard hats, on the other hand, offer additional protection against lateral impacts, including side impacts and penetration. Type 2 hard hats are typically recommended for construction workers and other roles where side impact risks are present.

What are the different styles of hard hats?

The style of hard hats refers to the level of impact protection and the specific design features they offer. We offer a range of hard hat styles, including hydro-dipped, full brim, cap brim, cowboy/western, vented, low profile, as well as options with chin straps and bump caps, to suit various worksite needs and personal preferences.

What is the ANSI standard for hard hats?

The ANSI standard for hard hats ensures that they meet specific performance and testing criteria for industrial use. Hard hats are classified into two types and three classes:

- Type I: Provides protection from impacts to the top of the head.

- Type II: Offers protection from impacts to both the top and sides of the head.

- Class G (General): Rated for low-voltage protection up to 2,200 volts.

- Class E (Electrical): Rated for high-voltage protection up to 20,000 volts.

- Class C (Conductive): Provides no electrical protection and is designed for comfort and lightweight protection.

Meeting these ANSI standards ensures that hard hats provide adequate safety for various industrial purposes.

What are the OSHA hard hats requirements?

OSHA (Occupational Safety and Health Administration) requirements for hard hats mandate that they must comply with ANSI standards to ensure adequate protection. Hard hats must provide effective protection against potential hazards such as falling objects, electrical shocks, and impacts. They should meet OSHA regulations for workplace safety, ensuring enhanced head protection for workers in environments with potential risks.

How to wear a hard hat correctly?

To wear a hard hat correctly, ensure it fits snugly on your head with the suspension straps adjusted to create space between the hard shell and your head. This space helps with ventilation and provides better impact protection. The hard hat should sit level on your head, covering the forehead without tilting forward or backward, and the adjustable suspension should be tightened to keep it secure and comfortable.

How long are hard hats good for?

A hard hat should be replaced immediately if it shows signs of damage such as dents, cracks, or penetration, or if it has been subjected to rough treatment. Even without visible damage, hard hats should generally be replaced in 3-5 years to ensure maximum protection. Additionally, the suspension system should be replaced every 12 months to maintain proper support and safety.

What colour hard hat do engineers wear?

Engineers typically wear white hard hats, which help increase their visibility and distinguish them from other workers on the job site or work place.

Which class of hard hats protect from electrical shock?

Class G (General) and Class E (Electrical) hard hats are both designed for protection against electrical shock. Class G hard hats are rated to provide protection up to 2,200 volts, while Class E hard hats offer a higher level of electrical protection, rated up to 20,000 volts. These classifications ensure that workers have the appropriate level of head protection when working around electrical hazards.